Tecnofirma is at the forefront in the study and implementation of innovative solutions for the E-Mobility

Primary objectives always remain: research, engineering, quality and product excellence.

Monza. In the ongoing transition phase, in which technological evolutions travel exponentially, Tecnofirma continues to study and design innovative solutions for its cleaning, painting, impregnation machines in order to give an effective response to the rapidly changing automotive industry.

For twenty years the company has been manufacturing impregnation machines for electric motors. Currently Hairpin motors are one of the most important innovations towards vehicle electrification, with great advantages in terms of thermal and electrical efficiency.

Tecnofirma’s current offer of impregnation machines for Hairpin motors provides different solutions according to the type of production needs and the impregnation technology to be applied.

The company matches the expectations of the most renowned car manufacturers who apply this engine to the new powertrain of electrified cars.

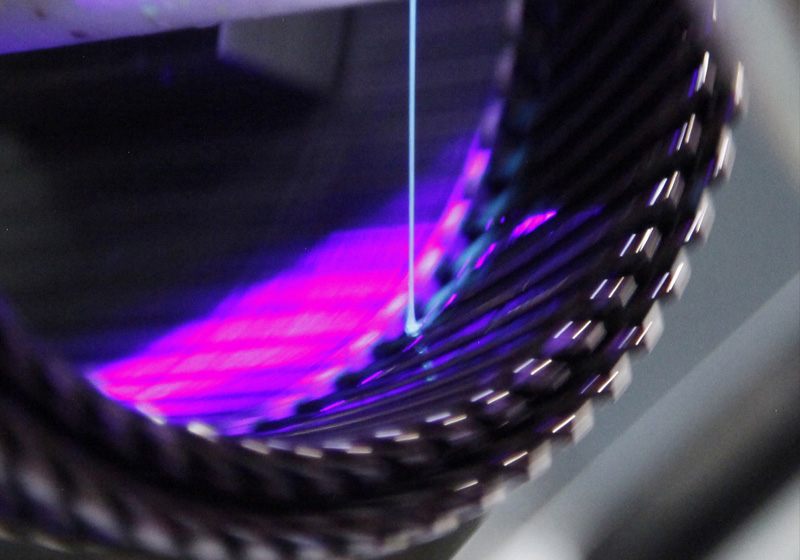

In particular, the company has been able to evolve the Trickling technology - application of resin by dripping - into Flexible Trickling, an unconventional impregnation method, which is perfectly suited for the high saturation requirements of the Hairpin motor. This has been made possible thanks to the targeted and in-depth study of the process in all its phases, from the preheating of the piece to its cooling.

The current range of Tecnofirma includes 4 lines of impregnation machines: Camelot, Ring, Pilot, U line. Each machine adapts to the needs of different production volumes. For the treatment of Hairpin motors, Tecnofirma makes available the Pilot range, very flexible and compact, aimed at medium-low production rates, for customers who want to include it within their own motor production line. It also includes the U line type, aimed at high production volumes. Both can be configured with optional processes for the application of insulating products to cover the welds of Hairpin motors.

Customer care is guaranteed beginning to the design phase, thanks to a problem-solving laboratory that makes use of a team of highly specialized professionals, and continues until the after-sales. This support is highly appreciated and recognized by customers, who today privilege Trickling technology as it provides significant benefits such as more compact systems, reduced operating costs, lower environmental impact. It also guarantees greater speed, more precision and therefore less contamination of the external surface of the treated parts.

Tecnofirma's challenge is to enhance research and study always new solutions to keep up with the rapid evolution of the electric motor towards e-mobility.