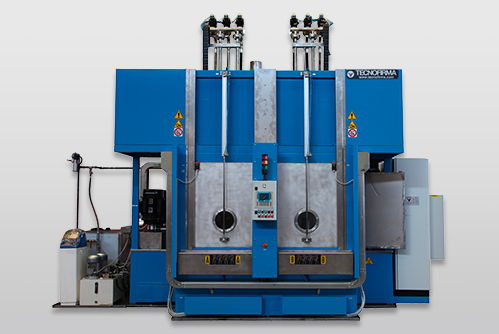

In order to response to different washing needs, Tecnofirma can develop specialized custom booth washers. The booth washer is usually used in low production rate and can be used not only for general washing process, but also for high quality process for products with high complexity. Among Tecnofirma production there are also specific series for the pallet washing operation on the assembly lines.

Parts treated

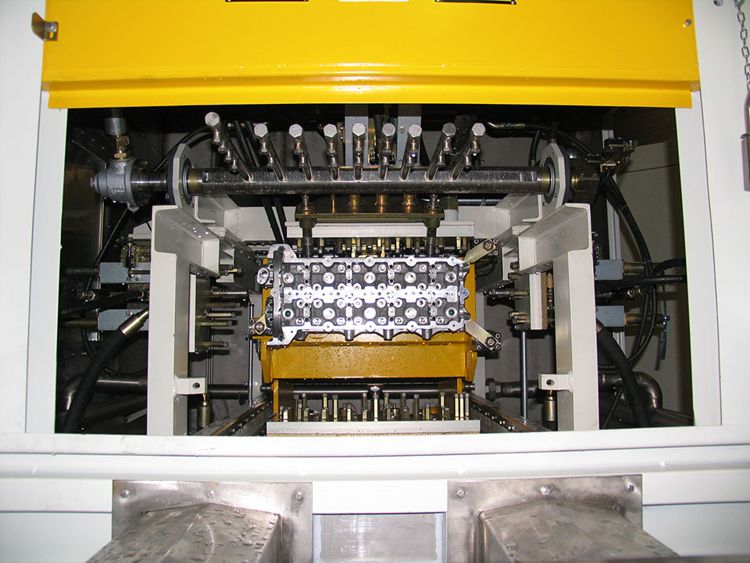

Parts include, but are not limited to crankshafts, engine heads, engine blocks, power steering, hydraulic valves, turbine blades, pallets, tools, bodies of fans, oil and gas valves, rolling mill-made parts

Cycle time

- Minimum 2 minutes

Standard processes

- Washing

- Blowing

- Drying

Optional processes

- Rinsing

- Immersion washing

- Ultrasonic cleaning

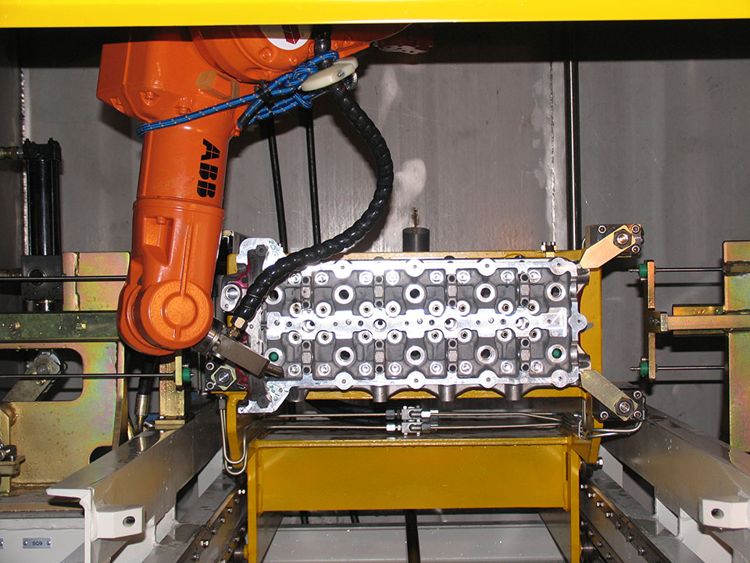

- Robotic washing

- HP deburring

- Vacuum drying