Electric winding impregnation optimizes the product overall performance, increases the coil insulation, the resistance to stress and temperature generated during normal operation. It also minimizes the risk of short circuits in the windings and increases heat exchange, extending motor working life.

Tecnofirma takes care of your products by studying and applying the best impregnation process for each customer. An incorrect method or insufficient impregnation can considerably shorten the working life of your electric motor.

Tecnofirma offers a wide range of solutions for the insulation of traditional and new-generation windings. We develop in our lab the best impregnation technology/method, based on the foreseen application type.

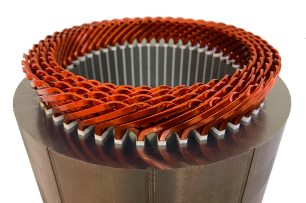

Stator with innovative design. We offer specific technological solutions and dedicated plants for Hairpin winding.

Learn more…

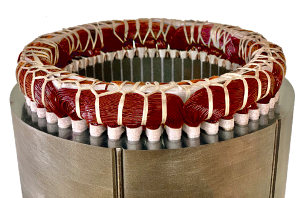

The best impregnation method for traditional winding rotors and stators.

Learn more…Over the years, Tecnofirma has developed alternative thermal processes used today in various plants as a replacement or in combination with traditional convection ovens according to production needs. In particular, combining multiple methods where are high cadences is necessary.